TUV CQC Approval 1500V 2.5mm2/4mm2/6mm2/10mm2/20mm2 PV Cabel Red and Black Cable XLPE Jacket Solar Wire Cable Solar

Hebei Huatong Wires & Cables Group Co., Ltd.- Application:Power Station

- Material Shape:Round Wire

- Sheath Material:Xlpo

- Insulating Material:XLPE

- Conductor Type:Stranded

- Brand:Ht Cable

Base Info

- Model NO.:solar cable

- Certification:TUV

- Wire Core Material:Tinned Wire

- Model Number:Solar Cable

- Standard:En50618

- Cross Section:4 mm2

- Rated Voltage:1500V

- Certificate:TUV

- Sheath:Xlpo

- Insulation:Xlpo

- Conductor:Flexible Copper

- Manufacturer:Ht Cable

- Transport Package:Standard Export Drums

- Specification:4mm2

- Trademark:HT Cables

- Origin:China

- HS Code:8544492100

- Production Capacity:1000000meter Per Month

Description

Basic Info.

Model NO. solar cable Certification TUV Wire Core Material Tinned Wire Model Number Solar Cable Standard En50618 Cross Section 4 mm2 Rated Voltage 1500V Certificate TUV Sheath Xlpo Insulation Xlpo Conductor Flexible Copper Manufacturer Ht Cable Transport Package Standard Export Drums Specification 4mm2 Trademark HT Cables Origin China HS Code 8544492100 Production Capacity 1000000meter Per MonthProduct Description

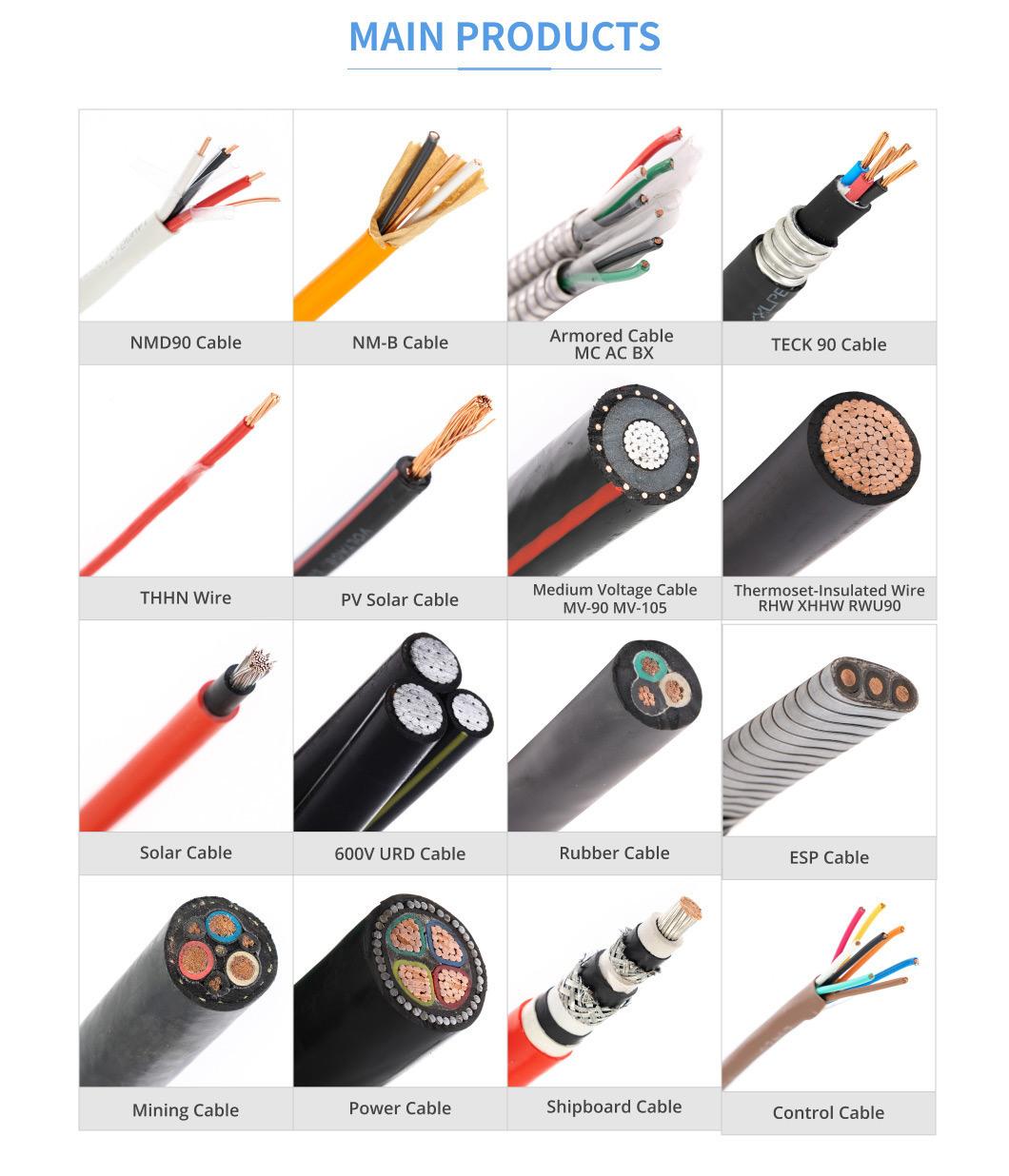

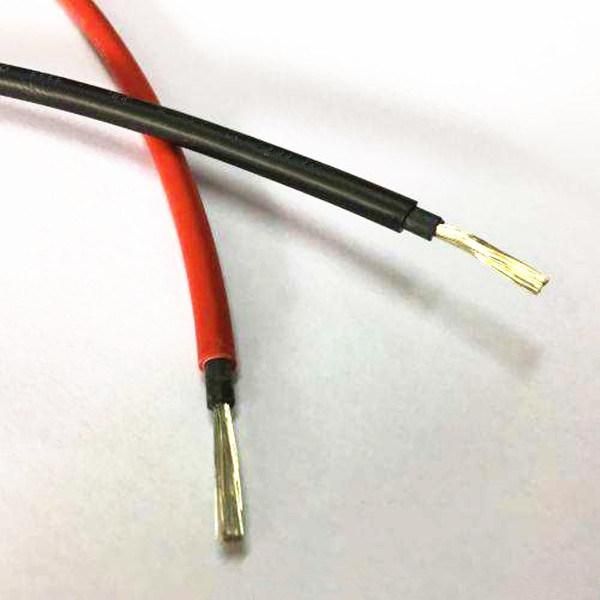

TUV Approval 1500V 2.5mm2/4mm2/6mm2/10mm2/20mm2 PV cabel red and black cable XLPE jacket solar wire cable solar

TOP TEN CABLE MANUFACTURER IN CHINA

LARGEST CABLE MANUFACTUER IN NORTH CHINA

ANNUAL EXPORT VOLUME EXCEED 200MILLION USD

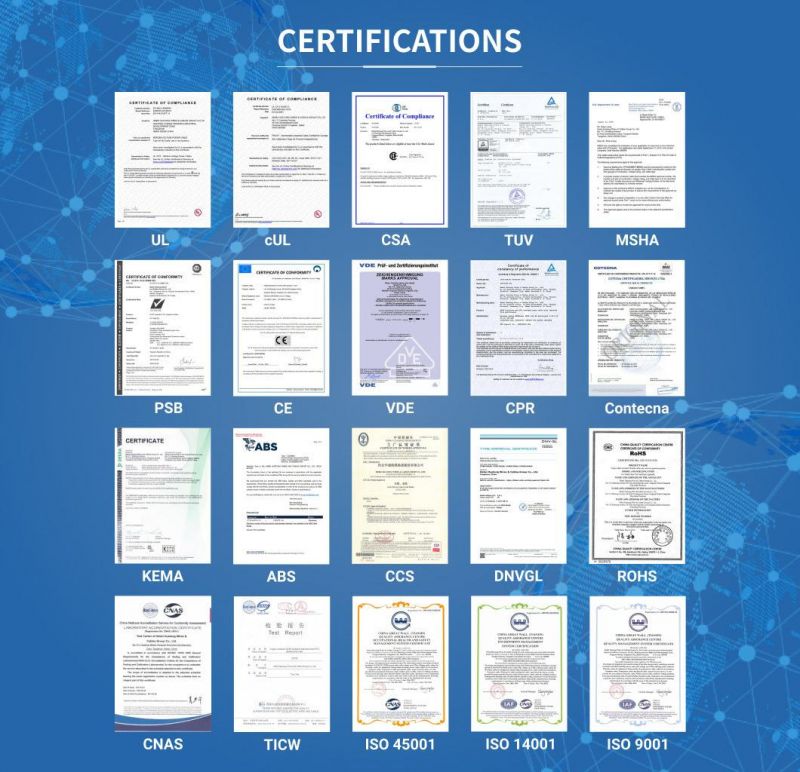

WITH UL,TUV,KEMA,CE,BV,PSB,SABS,LLOYD'S,GL,NK,KR,ABS PRODUCTS CERTIFICATIONS

WITH TUV TYPE TESTING REPORT

WIDE PRODUCTS RANGE

ISO9001,ISO18001,OHSAS18001 SYSTEM CERTIFICATIONS

CNAS APPROVAL LABROTARY

Application

For the cabling between the solar modules and as extension cable between the module strings and the DC/AC inverter Gable and flat roof photovoltaic systems Photovoltaic plants and solar parks Flexible or building-integrated PV systems including connecting photovoltaic power supply systems & can be used indoor & outdoor for flexible and fixed installations with high mechanical strength in extreme weather conditions. from - 40 deg.C to 120 deg.C maximum and Ozone & UV Resistant and full protection against Ultra Violet rays.

Product Features

Weather/UV-resistant acc. to HD 605/A1

Ozone-resistant according to EN 50396

Halogen-free and flame-retardant

Good notch and abrasion resistance

XLS-R = X-Linked Standard - Reduced Proven electron beam cross-linked quality

Cold Flexibility

Long Life about > 25 years

Suitable to common connector type

Standard to follow

EN50618 Standard

Conductor

Tinned fine copper strands, according to IEC 60228, class 5

Insulation

Cross Linked polyolefin-copolymer Double Insulated Temperature resistant and halogen free , Flame Retardant, Low Smoke.

Color of Insulation

Black, red, blue

Outer Sheath

Flame retardant and halogen free Co-Polymer, electron beam cross linked, Weather proof & UV Resistant. Color - Black

Electrical Properties

Nominal voltage U0/U acc. VDE AC 600/1000 V - 720/1200 V & DC 900/1800 V

Max. permitted DC voltage 1.8 kV (Conductor/Conductor. non earthed system

Working voltage : According to. TÜV 2 PfG 1169 DC 1000 V

Test voltage AC 6,5 kV for 5 min & DC 15 KV.

Voltage resistance tests according to EN 50395

Insulation Resistance - 1000 m-OHM / km minimum

Specification

| SIZE cross-sectional area in | Number of Strands and diameter | Nominal Insulation Thickness | Nominal Sheath Thickness | Max. Conductor D.C Resistance at 20 °C | Approx. Overall Diameter of cable (in mm) | Weight |

| mm2 | n/mm | mm | mm | ohm/(km) | mm | Kg/km |

| 1.5 | 28/0.25 | 0.75 | 0.95 | 13.7 | 4.60 +/- 0.5 | 41 |

| 2.5 | 46/0.25 | 0.75 | 0.95 | 8.21 | 5.00 +/- 0.5 | 52 |

| 4 | 52/0.3 | 0.75 | 0.95 | 5.09 | 5.50 +/- 0.5 | 70 |

| 6 | 78/0.3 | 0.75 | 0.95 | 3.39 | 6.00 +/- 0.5 | 91 |

| 10 | 77/0.4 | 0.75 | 0.95 | 1.95 | 7.20 +/- 0.5 | 138 |

| 16 | 119/0.4 | 0.75 | 0.95 | 1.24 | 8.80 +/- 0.5 | 197 |

| 25 | 189/0.4 | 1.0 | 1.05 | 0.795 | 10.50 +/- 0.5 | 307 |

| 35 | 252/0.4 | 1.0 | 1.05 | 0.565 | 11.50 +/- 0.5 | 394 |