Ho1n2-D CE Certified BS 638 Based 100V Tinned Copper 0361tq Double Insulated Arc Welding Cable for Welding Machines in Wholesale Control Wire Cable

Tianjin Feiya Electric Wire & Cable Co., Ltd.- Application:Construction, Overhead, Underground, Industrial, Power Station, Telecommunication, Computer, Car, Installation in Ground, Indoors, Outdoors.

- Voltage:Low and Medium Voltage Cable

- Current:DC & AC

- Insulation Material:Epr Gp4(Ethylene Propylene Rubber) to BS7655

- Sheath Material:Polychloroprene Rubber (Neoprene) Sheath Em5, Hofr

- Material Shape:Round Wire

Base Info

- Model NO.:Mining Cable

- Wire Core Material:Extra Fine Bare,Tinned Copper Strands

- Certification:ISO, CCC, CE, RoHS, UL, VDE

- Model:0361tq

- Brand:Feiya

- Temperature Range:-25 Degree to +85 Degree

- OEM&ODM:Yes

- Rated Voltage:100V

- Operating Environment:Domestic Premises, Such as Kitchens and Offices

- Other Service:Can Be Customized

- Colors:Can Be Customized

- Transport Package:Wooden Box Packing or Pallet Shipping Containers

- Specification:BS 6360 CL-6, or CL-5 (120mm and above)

- Trademark:Feiya

- Origin:China

- HS Code:8544

- Production Capacity:80000 Meter,Meters Per Month

Description

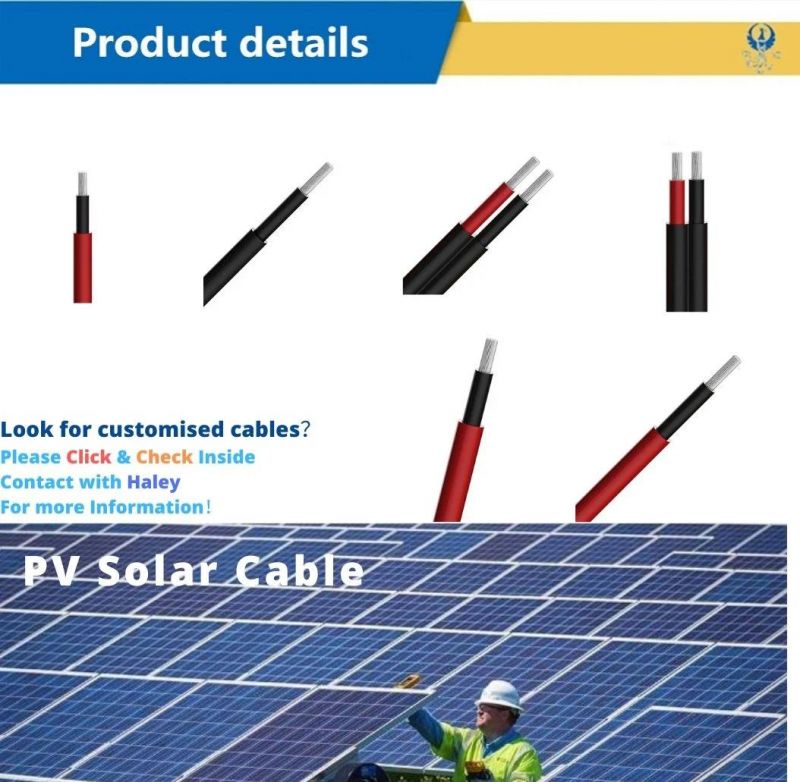

Solar Cable

H1Z2Z2-K | PV1-F

Conductor: Tinned copper, elecreical property & Structure in accordance with EN60228 Class 5.Insulation: LSZH electron-beam cross-linked Polyolefin copolymer ROHS material.

Outer sheath: LSZH & UV-resistant electron-beam cross-linked Polyolefin copolymer ROHS material.

Colour: Prior colour black,or as per customer's request.H1Z2Z2-K 35mm2 Dc Solar PV Cable EN50618.

| Conductor | Tinned Fine Re Copper Strand, according to VDE0295/IEC60228. Class 5 |

| Insulation | Polyolefin Copolymer electron-beam coss-linked |

| Sheath Jacket | Polyolefin Copolymer electron-beam coss-linked |

| Nominal Voltage | Uo/U=1000VAC, 1500VDC |

| Test Voltage | 6500V, 50Hz, 5Min |

| Temperature Rating | -40°C-120°C ,More than 25 Years (EN 50618) |

| Fire Performance | IEC 60332-1 |

| Smoke Emission | IEC61034, EN 50286-2 |

| Low Fire Load | DIN 51 900 |

| Certification | EN 50618 Standard |

Product parameters

| Cross section(mm2) | Conductor Construction | Outer(mm) | Resistance Max. | Current Carring Capacity |

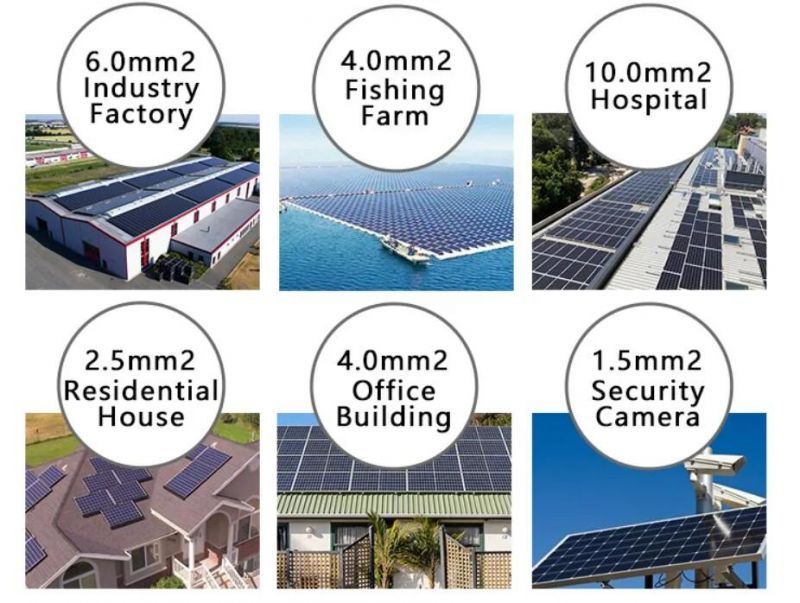

| 1*1.5 | 30/0.25 | 4.90 | 13.30 | 30 |

| 1*2.5 | 50/0.25 | 5.45 | 7.89 | 41 |

| 1*4 | 56/0.3 | 6.10 | 4.75 | 50 |

| 1*6 | 84/0.3 | 7.20 | 3.39 | 70 |

| 1*10 | 142/0.3 | 9.00 | 1.95 | 98 |

| 1*16 | 228/0.3 | 10.20 | 1.24 | 132 |

| 1*25 | 361/0.3 | 12.00 | 0.795 | 176 |

| 1*35 | 525/0.3 | 13.8 | 0.565 | 218 |

| 1*50 | 720/0.3 | 14.8 | 0.393 | 280 |

| 1*70 | 988/0.3 | 16.9 | 0.277 | 350 |

| 1*95 | 1349/0.3 | 18.7 | 0.21 | 410 |

| 1*120 | 1691/0.3 | 20.7 | 0.164 | 480 |

| Cross section(mm2) | Conductor Construction | Outer(mm) | Resistance Max. | Current Carring Capacity |

| 2 x 1.5 | 30/0.25 | 8.3 ± 0.2 | 13.30 | 30 |

| 2 x 2.5 | 50/0.25 | 9.2 ± 0.2 | 7.98 | 41 |

| 2 x 4 | 56/0.3 | 12.0 ± 0.2 | 4.75 | 50 |

| 2 x 6 | 84/0.3 | 13.5 ± 0.2 | 3.39 | 70 |

| 2 x 10 | 142/0.3 | 17.6 ± 0.2 | 1.95 | 98 |

| 2 x 16 | 228/0.3 | 19.8 ± 0.2 | 1.24 | 132 |