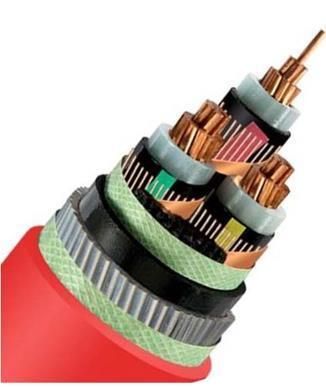

3X35/16mm2 N2xseyfgby 6/10 (12) Kv High Voltage Copper XLPE Insulated Cable

Henan Hongda Cable Co., Ltd.- Application:Construction, Overhead, Underground, Industrial, Power Station

- Voltage:Low and Medium Voltage Cable

- Current:DC Cable

- Insulation Material:XLPE

- Sheath Material:PVC

- Material Shape:Round Wire

Base Info

- Model NO.:N2XSEYFGBY

- Wire Core Material:Red Copper Wire

- Certification:ISO, CCC, CE

- Model:N2xseyfgby

- Brand:Hongda

- Packing Length:1000m,Drum

- Warranty:One Year

- Color:Red or Black

- Transport Package:Steel & Wooden Drum

- Specification:3x35,16mm2

- Trademark:HONGDA

- Origin:China

- HS Code:8544601200

- Production Capacity:10km,Month

Description

Basic Info.

Model NO. N2XSEYFGBY Wire Core Material Red Copper Wire Certification ISO, CCC, CE Model N2xseyfgby Brand Hongda Packing Length 1000m/Drum Warranty One Year Color Red or Black Transport Package Steel & Wooden Drum Specification 3x35/16mm2 Trademark HONGDA Origin China HS Code 8544601200 Production Capacity 10km/MonthProduct Description

3x35/16mm2 N2XSEYFGBY 6/10(12)kV HIGH VOLTAGE COPPER XLPE INSULATED CABLEApplication

They are used in cable ducts, outdoor installations, underground where the short circuit levels are high and industrial areas fed by electrical energy also these cables use where there is risk of mechanical damage.

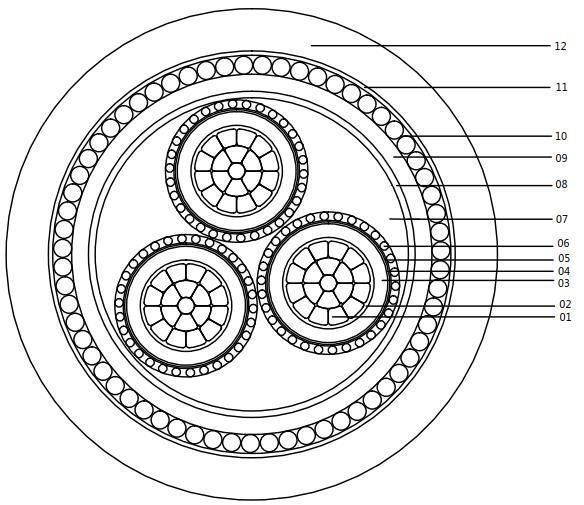

01: Copper Conductor

02: Conductor Screen

03: XLPE Insulation

04: Insulation Screen

05: Semi-Conductive Tape

06: Copper Wire and Copper Tape Screen

07: PVC Filler

08: Binding Tape: non-hygroscopic tape

09: PVC Inner Sheath

10: Galvanised Round Steel Wire Armour

11: Binding Tape: non-hygroscopic tape

12: PVC Outer Sheath

Technical Data

| DESCRIPTION | UNIT | Supplier's Offer |

| GENERAL | ||

| Cable Code | N2XSEYFGBY | |

| Applied Standards | IEC 60502-2 | |

| Voltage Rate (U0) | kV | 6 |

| Voltage Rate (U) | kV | 10 |

| Max. Operating Voltage (Um) | kV | 12 |

| 01: Conductor | ||

| Material | - | Plain annealed copper (free oxygen) |

| Cross-Section Area | mm² | 35 |

| Number & Diameter of Wires | No.*mm | 7*2.56 |

| Type of Stranding | CIRCULAR COMPACTED | |

| Outer Diameter (Approx.) | mm | 7.00 |

| Number of Core | No. | 3 |

| 02: Conductor Screen | ||

| Material | Extruded semi-conductive compound | |

| Nominal Thickness | mm | ≥0.5 |

| Minimum Thinkness | mm | ≥0.3 |

| Outer Diameter (Approx.) | mm | ≥8.0 |

| 03: Insulation | ||

| Material | XLPE | |

| Nominal Thickness | mm | ≥3.40 |

| Minimum Thickness | mm | ≥2.96 |

| Outer Diameter (Approx.) | mm | ≥14.80 |

| 04: Insulation Screen | ||

| Material | Extruded semi-conductive compound | |

| Nominal Thickness | mm | ≥0.50 |

| Minimum Thickness | mm | ≥0.30 |

| Outer Diameter (Approx.) | mm | ≥15.80 |

| 05: Semi-Conductive Tape | ||

| Tape Thickness | mm | 0.20 |

| 06: Metallic Screen | ||

| Material | Copper | |

| Type | Wire & Tape | |

| Number & Diameter of Wires | No.*mm | 12*0.85 (on each core) |

| Thickness & Width of Copper Tape | mm*mm | 0.10*(≥10)(on each core) |

| Tape for Protection | mm | |

| Outer Diameter (Approx.) | mm | ≥17.40 |

| Total Cross Section Area | mm² | ≥16.00 |

| 07: Filler | ||

| Material | PVC | |

| 08: Binding Tape: non-hygroscopic tape | ||

| Nominal Thickness | mm | 0.20 |

| 09: Inner Sheath | ||

| Material | PVC | |

| Nominal Thickness | mm | ≥1.40 |

| Minimum Thickness | mm | ≥0.92 |

| 10: Metallic Armour | ||

| Material | Galvanised Round Steel Wire | |

| Number*Diameter of Wires | No.*mm | (32~55) * 2.50 (up to IEC standard) |

| Thickness of Steel Tape | mm | ≥0.30 |

| Width of Steel Tape | mm | ≥20.00 |

| Binding Ratio | % | - |

| 11: Binding Tape: non-hygroscopic tape | ||

| Nominal Thickness | mm | 0.20 |

| 12: Outer Sheath | ||

| Material | PVC | |

| Colour | Red | |

| Nominal Thickness | mm | ≥2.60 |

| Minimum Thickness | mm | ≥1.88 |

| Electrical Properties | ||

| Test Voltage of 5 Minutes Duration | kV-rms | 21 |

| Impulse Test Voltage | kV-Peak | 75 |

| Continuous Current Carrying Capacity in Air at 30ºC | A | 182 |

| Continuous Current Carrying Capacity in Ground at 20ºC | A | 182 |

| Continuous Current Carrying Capacity in Duct | A | 163 |

| Ambient Temperature of Air | ºC | 30 |

| Soil Temperature | ºC | 20 |

| Depth of Laying | m | 0.8 |

| Thermal Resistivity of Soil | Km/W | 1.5 |

| Inductance | mH/km | 0.385 |

| Capacitance | μF/km | 0.226 |

| Insulation Resistance | MΩ/km | 14629 |

| Dielectric Losses (at 90ºC, 3phases) | W/km | 30.672 |

| Max. Continuous Conductor Temperature | ºC | 90 |

| Max. Conductor Temperature at Short Circuit Condition | ºC | 250 (5s max. duration) |

| Maximum Short-Circuit Current | ||

| Start Temperature 90ºC, End Temperature 250ºC | ||

| Duration of 5 seconds | kA | 2.24 |

| Duration of 1 seconds | kA | 5.01 |

| Duration of 0.5 seconds | kA | 7.08 |

| Maximum Short-Circuit Current at Metallic Screen | ||

| Duration of 1 seconds | kA | 2.048 |

| Duration of 0.5 seconds | kA | 2.896 |

| Dielectric Loss Factor | ||

| At 90ºC(Maximum Operating Temperature) | 40x10^4 | |

| Conductor Resistance at 20ºC | Ω/km | 0.5240 |

| Conductor Resistance at 90ºC | Ω/km | 0.6682 |

| Charging Current | A/km | 0.43 |

| Partial Discharge (at 2 U0) | pC | 5.00 |

| Other Properties | ||

| Outer Diameter of Cable (Approx.) | mm | ≥50.60 |

| Minimum Bending Radius | mm | ≥759 |

| Lowest Laying Temperature | ºC | -5.00 |

| Weight of Cable (Approx.) | kg/km | ≥4600 |

| Weight of Copper (Approx.) | kg/km | ≥1125 |

| Weight of Armour (Approx.) | kg/km | ≥1110 |

| Drums | ||

| Type | Steel & Wooden | |

| Flange (Wheel) Diameter | mm | 2200 |

| Barrel Diameter | mm | 900 |

| Barrel Length | mm | 1400 |

| Length of Cable | m | 1000 |

| Gross Weight | kg | ≥5225 |