Down Sized 300f Composite Duct Micro Cable (GYTA)

Zhejiang Fuchunjiang Photoelectric Science Technology Co., Ltd.- Application:Communication

- Type:Single-mode Fiber

- Connection Structure:SC

- Material Shape:Round Wire

- Allowed Lateral Pressure:100(N,100mm)<1000(N,100mm)

- Allowed Tensile Strength:1000N<10000N

Base Info

- Model NO.:GYTA

- Core:Multicore

- Certification:ISO9001

- Brand:OEM

- Sheath Material:PE

- Size:Small

- Temperature:-40ºC ~ +70ºC

- Installation:in Ducts

- Resistance:Longitudinal Water Resistance

- Transport Package:Drum

- Specification:Plastic

- Trademark:FCJ OPTO TECH

- Origin:China

- HS Code:8544700000

- Production Capacity:20 Million Kilometers

Description

Basic Info.

Model NO. GYTA Core Multicore Certification ISO9001 Brand OEM Sheath Material PE Size Small Temperature -40ºC ~ +70ºC Installation in Ducts Resistance Longitudinal Water Resistance Transport Package Drum Specification Plastic Trademark FCJ OPTO TECH Origin China HS Code 8544700000 Production Capacity 20 Million KilometersProduct Description

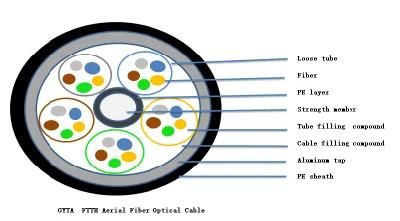

The bending insensitive optical Fibers, Easy Band® Plus-Mini(200 μm), are housed in loose tubes that are made of high-modulus plastic and filled with tube filling compound. The loose tubes with smaller size are stranded to form sub-units. The composite structure is formed by stranding sub-units, armoring with laminated aluminum tape and then extruding a PE outer sheath. This structure allows the optical cable to exceed 216 Fibers (in 18 units), which enhances installation density of Fibers in ducts.The length of delivery

• Standard length: 2,000m; other lengths are also available.

Features

• Accurate process control ensuring good mechanical and temperature performances

• The material of loose tubes with good hydrolysis resistance and relatively high strength

• Tube filling compound providing the key protection for Fibers

• Using small-sized B6a2 Fibers with good micro and macro bending performance

• High Fiber density

• Comply with IEC60794-3-11(2007): Optical Fiber cables- Part 3-11

• Water resistance of optical cable is ensured by the following measures:

• Special water-blocking compound filled in loose tubes

• Laminated aluminum tape armor

• Cable filling compound ensuring longitudinal water resistance

Technical Characteristics

| Type | Stranded units | Fiber count | Cable diameter (mm) | Cable weight (Kg/km) | Sheath thickness (mm) | Bending radius Dynamic/static (mm) |

| GYTA(RS)-300B6a2(200μm) | 5×5 | 300 | 13.5 | 182 | 1.5 | 20D/10D |

Mechanical Characteristics

• Tensile strength (N) - long/short term: 300/1000

• Crush resistance (N/100mm) - long/short term: 300/1000

Color Sequence of Sub-units

| Sub-unit No. | 1 | 2 | 3 | 4 | 5 |

| Yarn color | Red | Yellow | White | White | White |

Environmental Characteristics

• Transport/storage temperature: -40ºC ~ +70ºC

Mechanical Performance Tests and Criteria

| Test | Testing method | Conditions | Acceptance criteria |

| Tensile | IEC60794-1-21 method E1 | TM = 1000N TL = 30% of TM. | The maximum Fiber strain should not be higher than 0.6% under TM load Additional attenuation ≤0.1dB after test No damage to outer jacket and inner elements |

| Impact | IEC60794-1-21 method E4 | Impact energy: 3J Impact number: 1 Impact points: 3 | Additional attenuation ≤0.1dB after test No damage to outer jacket and inner elements |

| Crush | IEC60794-1-21 method E3 | Load: 1000N/100mm Duration time: 1min | Additional attenuation ≤0.1dB after test No damage to outer jacket and inner elements |

| Torsion | IEC60794-1-21 method E7 | Cycles:5 Length under test: 2m Turns: ± 180° | Additional attenuation ≤0.1dB after test No damage to outer jacket and inner elements |

| Repeated bending | IEC60794-1-21 method E6 | Bending radius: 20*D Cycles: 25 | No damage to outer jacket and inner elements |