H01n2-D/E Rubber Sheath Cable Electric Cable Wire Waterproof Welding Rubber Cable

Tianjin Feiya Electric Wire & Cable Co., Ltd.- Type:Insulated

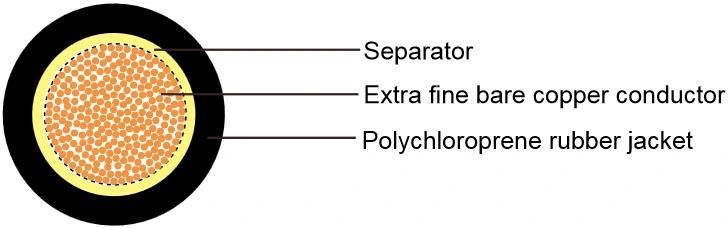

- Conductor Type:Stranded

- Application:Overhead, Underground

- Conductor Material:Copper

- Sheath Material:Rubber

- Insulation Material:Rubber

Base Info

- Model NO.:H01n2-D,E

- Material Shape:Round Wire

- Range of Application:Flame Retardant

- Certification:ISO9001, CE, UL, CCC, RoHS, VDE

- Brand:Feiya

- Color:Black Red Yellow, According to Voltage Level

- Whether It Is Environmentally Friendly:Yes

- Whether Quality Inspection:Provide Inspection Certificate

- Standard:Customized According to Specified National Standar

- OEM/ODM:Accepted

- Core:Single Core and Multicore

- Transport Package:Standard Export Packaging

- Specification:International General Specifications

- Trademark:Fengda

- Origin:Tianjin, China(Mainland)

- HS Code:8544492100

- Production Capacity:100000,Day

Description

Application and Description

These cables are used as a connection between the welding generator, the hand-electrode and the work piece. For use in the automobile industry, ship building, transport and conveyor systems, tool making machinery, welding robots etc.

These cables retain their high flexibility even under influence of ozone, light, oxygen, protective gases, oil and petrol. Robust cable structure of these cables makes them resistant to low and high temperature, fire, ozone and radiation, oils, acids, fats and petrols.

These cables are also ideal for outside installation in dry, moist and wet areas.

Standard and Approval

- <HAR> HD22.6 S2

- VDE-0282 Part-6

- IEC 60332.3

- IEC 60754.1

- UNEL 35368

- CEI 20-22 II

- CEI 20-38

- CE low voltage directive 73/23/EEC & 93/68/EEC

- ROHS compliant

Technical Characteristics

| WORKING VOLTAGE | 100/100 volts |

|---|---|

| TEST VOLTAGE | 1000 volts |

| FLEXING BENDING RADIUS | 12.0 x Ø |

| FIXED BENDING RADIUS | 7.5 x Ø |

| FLEXING TEMPERATURE | -25 ºC to +80 ºC |

| FIXED TEMPERATURE | -40 ºC to +80 ºC |

| FLAME RETARDANT | IEC 60332.1 |

Cable Parameter

CABLES WITH STANDARD AND APPROVAL FLEXIBILITY

| AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

|---|---|---|---|---|---|

| # X MM² | MM | MM | KG/KM | KG/KM | |

| 8(320/32) | 1 x 10 | 2.0 | 7.7-9.7 | 96 | 135 |

| 6(512/32) | 1 x 16 | 2.0 | 8.8-11.0 | 154 | 205 |

| 4(800/32) | 1 x 25 | 2.0 | 10.1-12.7 | 240 | 302 |

| 2(1120/32) | 1 x 35 | 2.0 | 11.4-14.2 | 336 | 420 |

| 1(1600/32) | 1 x 50 | 2.2 | 13.2-16.5 | 480 | 586 |

| 2/0(2240/32) | 1 x 70 | 2.4 | 15.3-19.2 | 672 | 798 |

| 3/0(3024/32) | 1 x 95 | 2.6 | 17.1-21.4 | 912 | 1015 |

| 4/0(614/24) | 1 x 120 | 2.8 | 19.2-24.0 | 1152 | 1310 |

| 300MCM(765/24) | 1 x 150 | 3.0 | 21.2-26.4 | 1440 | 1620 |

| 350MCM(944/24) | 1 x 185 | 3.2 | 23.1-28.9 | 1776 | 1916 |

| 500MCM(1225/24) | 1 x 240 | 3.4 | 25.0-29.5 | 2304 | 2540 |

CABLES WITH EXTREME HIGH FLEXIBILITY

| AWG | NO. OF CORES X NOMINAL CROSS SECTIONAL AREA | NOMINAL THICKNESS OF INSULATION | NOMINAL OVERALL DIAMETER | NOMINAL COPPER WEIGHT | NOMINAL WEIGHT |

|---|---|---|---|---|---|

| # X MM² | MM | MM | KG/KM | KG/KM | |

| 8(566/35) | 1 x 10 | 1.2 | 6.2-7.8 | 96 | 119 |

| 6(903/35) | 1 x 16 | 1.2 | 7.3-9.1 | 154 | 181 |

| 4(1407/35) | 1 x 25 | 1.2 | 8.6-10.8 | 240 | 270 |

| 2(1974/35) | 1 x 35 | 1.2 | 9.8-12.3 | 336 | 363 |

| 1(2830/35) | 1 x 50 | 1.5 | 11.9-14.8 | 480 | 528 |

| 2/0(3952/35) | 1 x 70 | 1.8 | 13.6-17.0 | 672 | 716 |

| 3/0(5370/35) | 1 x 95 | 1.8 | 15.6-19.5 | 912 | 1012 |

| 4/0(3819/32) | 1 x 120 | 1.8 | 17.2-21.6 | 1152 | 1190 |

| 300MCM(4788/32) | 1 x 150 | 1.8 | 18.8-23.5 | 1440 | 1305 |

| 500MCM(5852/32) | 1 x 185 | 1.8 | 20.4-25.5 | 1776 | 1511 |