1.8/3.0 (3.6kV) Yjlv72, Al/XLPE/Cts/PVC/Awa/PVC Cable, 1X300mm2

Henan Hongda Cable Co., Ltd.- Application:Construction, Underground, Industrial

- Voltage:Low and Medium Voltage Cable

- Current:AC Cable

- Insulation Material:XLPE

- Sheath Material:PVC,PE

- Material Shape:Round Wire

Base Info

- Model NO.:YJLV72

- Wire Core Material:Copper or Aluminum

- Certification:ISO, CCC, CE, RoHS

- Model:Yjlv72

- Brand:Hongda

- Manufacture:Yes

- Sample:Yes

- Core:Generally One or Three

- Conductor Material:Copper,Aluminum

- Insulated Color:as Your Requirement

- Sheath Color:Black

- Standard:IEC60502 or IEC60228

- Armor:Swa,Awa,Sta

- Transport Package:Wooden Drum

- Specification:35-1000mm2

- Trademark:Hongda CABLE

- Origin:China, Henan

- HS Code:8544602100

- Production Capacity:300km,Per Months

Description

Voltage Rating N2XSY - single copper core XLPE insulated with PVC oversheath 6/10kV 12/20kV 18/30kV N2XS2Y - single copper core XLPE insulated with PE oversheath 6/10kV 12/20kV 18/30kV NA2XSY - single aluminium core XLPE insulated with PVC oversheath 6/10kV 12/20kV 18/30kV NA2XS2Y - single aluminium core XLPE insulated with PE oversheath 6/10kV 12/20kV 18/30kV N2XSEY - 3 copper core XLPE insulated with PVC oversheath 6/10kV N2XS(F)2Y - single copper core XLPE insulated with water blocking powder and PE oversheath 6/10kV 12/20kV 18/30kV N2XS(FL)2Y - single copper core XLPE insulated with water blocking powder and aluminium tape tightly bonded to PE sheath 6/10kV 12/20kV NA2XS(F)2Y - single aluminium core XLPE insulated with water blocking powder and PE oversheath 6/10kV 12/20kV 18/30kV NA2XS(FL)2Y - single aluminium core XLPE insulated with water blocking powder and aluminium tape tightly bonded to PE sheath 6/10kV 12/20kV 18/30kV

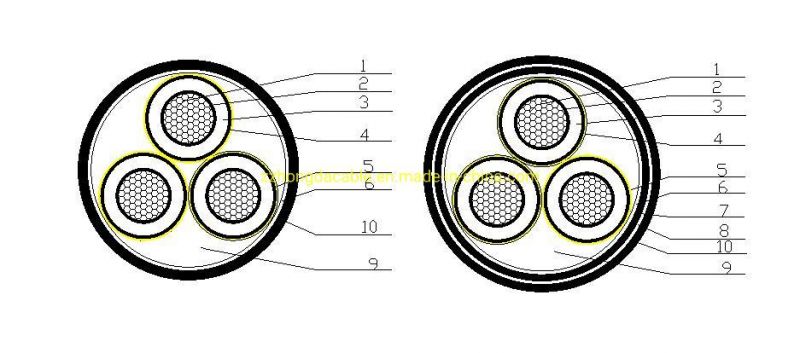

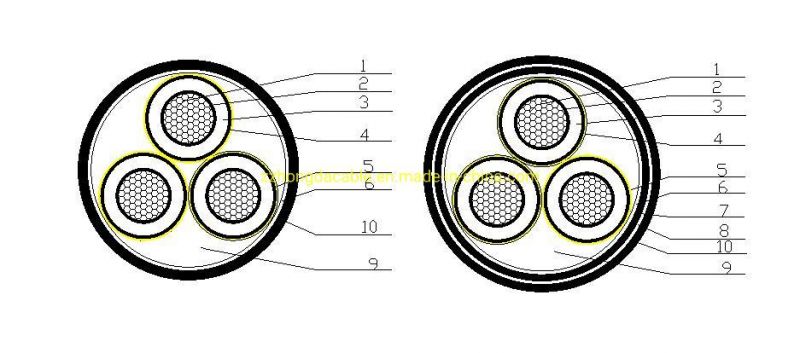

As a specialist MV cable supplier, our standard medium voltage cable portfolio contains cable with single and 3-core copper or aluminium conductors, with a steel wire armour or aluminium wire armour for mechanical protection, and with various application-specific materials including Polyvinyl Chloride (PVC), Polyethylene (PE), Cross-linked Polyethylene (XLPE) and Ethylene Propylene Rubber (EPR) and oversheathing properties including Low Smoke Zero Halogen (LSZH). We also supply medium voltage standard cables manufactured against specific power network requirements supplied in triplex formation. Our MV cable products are installed across a number of industries ranging from construction to power transmission. They are widely used for power distribution between high voltage mains power supply and low voltage applications, as well as by utility companies to connect residential and industrial complexes, or renewable energy sources such as wind and solar farms, to the primary grid.

Our MV cables are available in specific lengths as well as in extended long lengths to facilitate installation and to reduce the number of joints.

In addition to standard medium voltage cables, we can design and supply bespoke MV cable products developed for your specific applications. Our custom designed cable solutions provide for variants developed and manufactured around a number of parameters, including:

Cross-sectional area: generally 35mm2 up to 100mm2

Number of cores: generally one or three

Solid or stranded aluminium conductors: for applications requiring a lighter cable weight, also often more economical due to lower aluminium prices.

Stranded copper conductors: for applications requiring a smaller overall diameter and higher transmitting properties.

Bedding

Bonded or strippable out semi-conducting layer

Water tightness: longitudinal, longitudinal + quasi-radial, longitudinal + radial

Insulation layers (conductor screen, insulation and insulation screen): XLPE, which is more commonly used for MV cables, or EPR which is more flexible and often better suited to marine and offshore applications.

Metallic screen: to nullify the electric field outside the MV cable. Concentric copper wire screens, Aluminium foil laminate, or extruded lead alloy sheath.

Twisted three-core cable or triplex

Armouring: for mechanical protection. Aluminium wire armoured for single-core cables, Galvanised steel wire armour, strip or tape.

Tapes: Separator tapes to facilitate peeling, water-swellable tapes to prevent water ingress, Conductive tape for core binding.

Outer Sheath: compounds with various properties, tailored to the specific application's requirements, including resistance to oils, greases, rodents, termites, UV and flame, as well as zero halogen emissions.

Some of the tests you would expect from a medium voltage cable manufacturer, and which are performed on our MV cables, include:

Routine tests: These non-destructive tests are normally carried out on all lengths manufactured.

- Conductor resistivity

- Spark test on oversheath

- Voltage tests on sheath

- D.C. voltage test on oversheath

Sample tests: These potentially destructive tests are normally carried out on every production run.

- Examination of conductor and dimensions

- Hot set test for XLPE insulation

- Insulation and oversheath thickness

- Four hour voltage test

Type tests: These destructive tests are normally carried out in addition to the above tests on commencement of a particular cable supply to validate its design.

- Electrical type tests including bending and heat cycle

- Non-electrical type tests including mechanical properties after ageing and tests under fire conditions.

MV Cable Sizes

Our 10kV, 11kV, 20kV, 30kV and 33kV cables are available in the following cross-sectional size ranges. Larger sizes are available upon request.| 10kV single core | 35mm2 to 500mm2 |

| 10kV 3-core | 35mm2 to 240mm2 |

| 11kV single core | 50mm2 to 1000mm2 |

| 11kV 3-core | 35mm2 to 400mm2 |

| 20kV single core | 50mm2 to 500mm2 |

| 30kV single core | 50mm2 to 500mm2 |

| 33kV single core | 70mm2 to 1000mm2 |

European MV cable type designation

| N | MV cable according to DIN VDE 0276 |

| A | Aluminium (Al) conductor |

| [blank] | Copper (Cu) conductor |

| 2X | Cross-linked polyethylene (XLPE) insulation |

| S | Screen of copper wires and copper tape, helically wound |

| SE | Screen of copper wires and copper tape over each individual core, helically wound |

| Y | Polyvinyl Chloride (PVC) sheath |

| 2Y | Polyethylene (PE) sheath |

| (F)2Y | Longitudinal water tightness with PE sheath |

| (FL)2Y | Longitudinal and transversal water tightness with Al/PE sheath |

As a specialist MV cable supplier, our standard medium voltage cable portfolio contains cable with single and 3-core copper or aluminium conductors, with a steel wire armour or aluminium wire armour for mechanical protection, and with various application-specific materials including Polyvinyl Chloride (PVC), Polyethylene (PE), Cross-linked Polyethylene (XLPE) and Ethylene Propylene Rubber (EPR) and oversheathing properties including Low Smoke Zero Halogen (LSZH). We also supply medium voltage standard cables manufactured against specific power network requirements supplied in triplex formation. Our MV cable products are installed across a number of industries ranging from construction to power transmission. They are widely used for power distribution between high voltage mains power supply and low voltage applications, as well as by utility companies to connect residential and industrial complexes, or renewable energy sources such as wind and solar farms, to the primary grid.

Our MV cables are available in specific lengths as well as in extended long lengths to facilitate installation and to reduce the number of joints.

Custom designed medium voltage cables

In addition to standard medium voltage cables, we can design and supply bespoke MV cable products developed for your specific applications. Our custom designed cable solutions provide for variants developed and manufactured around a number of parameters, including:

Cross-sectional area: generally 35mm2 up to 100mm2

Number of cores: generally one or three

Solid or stranded aluminium conductors: for applications requiring a lighter cable weight, also often more economical due to lower aluminium prices.

Stranded copper conductors: for applications requiring a smaller overall diameter and higher transmitting properties.

Bedding

Bonded or strippable out semi-conducting layer

Water tightness: longitudinal, longitudinal + quasi-radial, longitudinal + radial

Insulation layers (conductor screen, insulation and insulation screen): XLPE, which is more commonly used for MV cables, or EPR which is more flexible and often better suited to marine and offshore applications.

Metallic screen: to nullify the electric field outside the MV cable. Concentric copper wire screens, Aluminium foil laminate, or extruded lead alloy sheath.

Twisted three-core cable or triplex

Armouring: for mechanical protection. Aluminium wire armoured for single-core cables, Galvanised steel wire armour, strip or tape.

Tapes: Separator tapes to facilitate peeling, water-swellable tapes to prevent water ingress, Conductive tape for core binding.

Outer Sheath: compounds with various properties, tailored to the specific application's requirements, including resistance to oils, greases, rodents, termites, UV and flame, as well as zero halogen emissions.

Medium Voltage cable testing

Our medium voltage cables including our BS6622 and BS7835 standard cables are tested by the Cable Lab®, our in-house specialist cable testing laboratory accredited by UKAS to ISO 17025. We perform tests on our cables against relevant British and international Standards, and against the requirements of your application when providing customised cable solutions.Some of the tests you would expect from a medium voltage cable manufacturer, and which are performed on our MV cables, include:

Routine tests: These non-destructive tests are normally carried out on all lengths manufactured.

- Conductor resistivity

- Spark test on oversheath

- Voltage tests on sheath

- D.C. voltage test on oversheath

Sample tests: These potentially destructive tests are normally carried out on every production run.

- Examination of conductor and dimensions

- Hot set test for XLPE insulation

- Insulation and oversheath thickness

- Four hour voltage test

Type tests: These destructive tests are normally carried out in addition to the above tests on commencement of a particular cable supply to validate its design.

- Electrical type tests including bending and heat cycle

- Non-electrical type tests including mechanical properties after ageing and tests under fire conditions.

Packaging&Delivery.

Packaging Details:Wooden drums,steel wooden drums or as your requirement

Delivery Time:Normally within 7 days(detailly depend on the order quantity)

Contact us

Looking forward to cooperation with you.If you have any question or need our certification and sample.Pls contact me freely.You can talk with me by Email or chat software.Tel:+86 15838290725